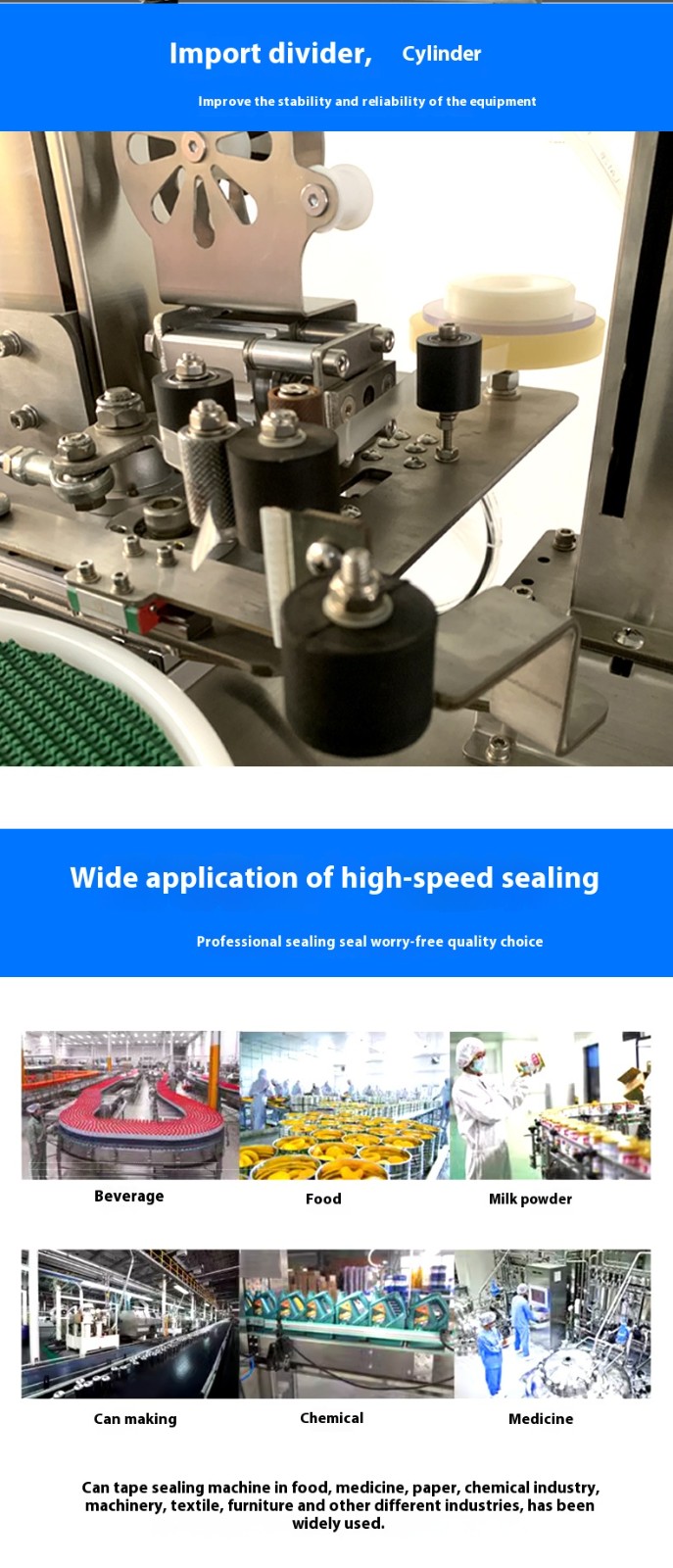

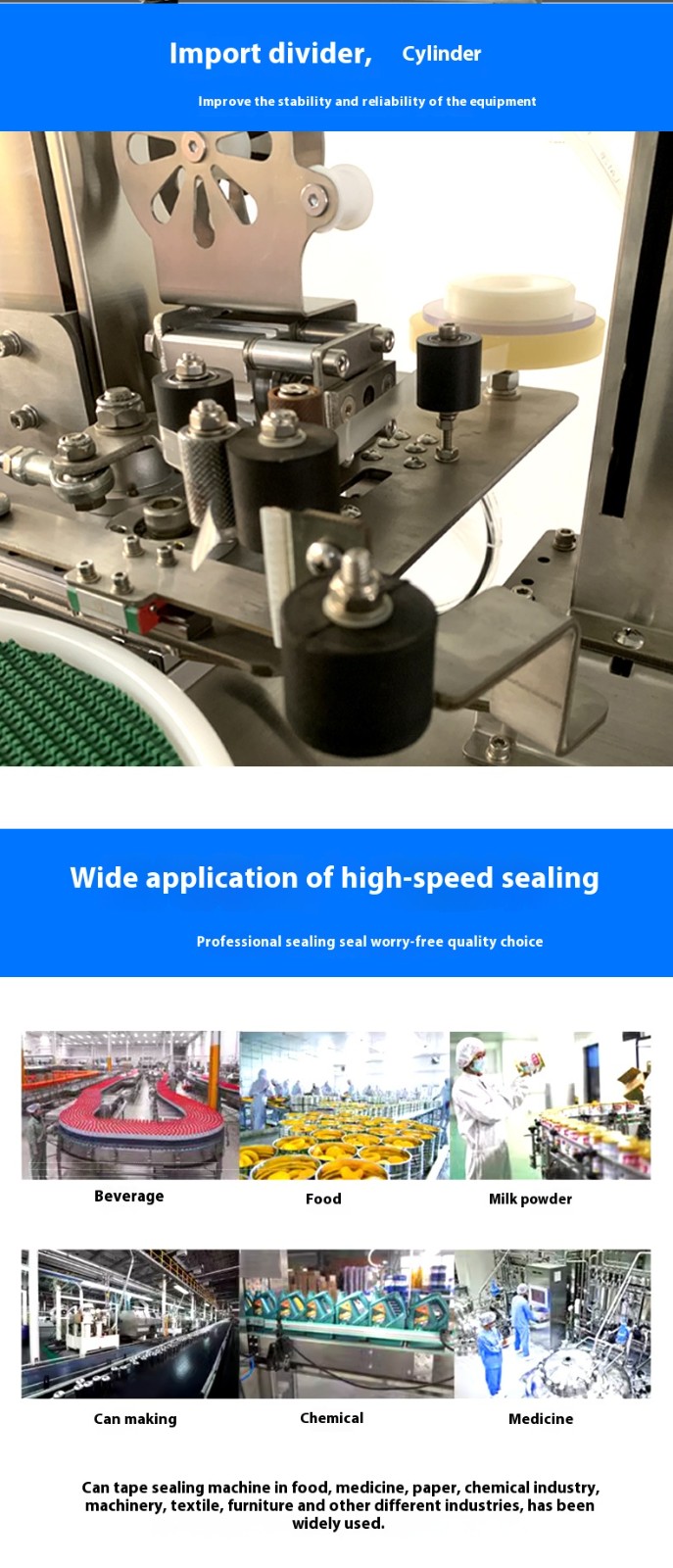

It adopts well-known brand components such as stepper motors and air cylinders, featuring high production efficiency, strong stability and reliability, and can reduce the labor intensity of workers.

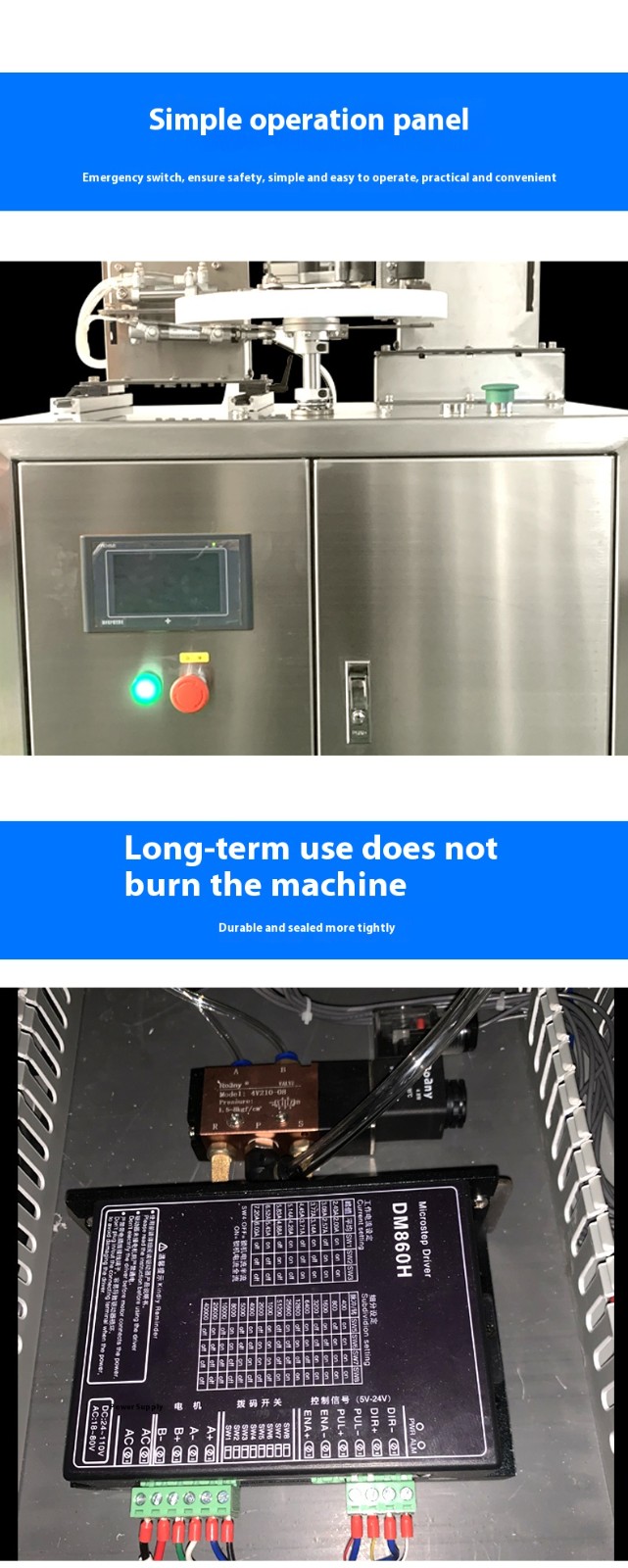

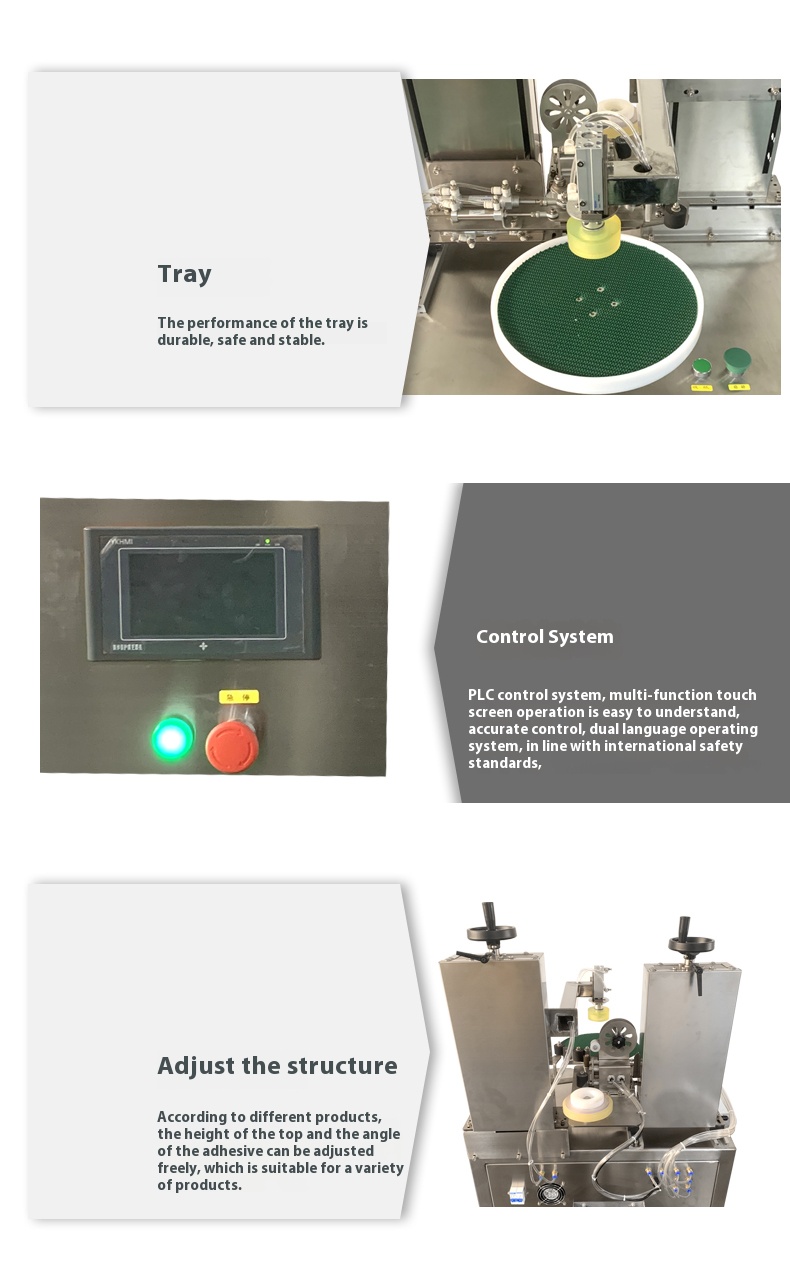

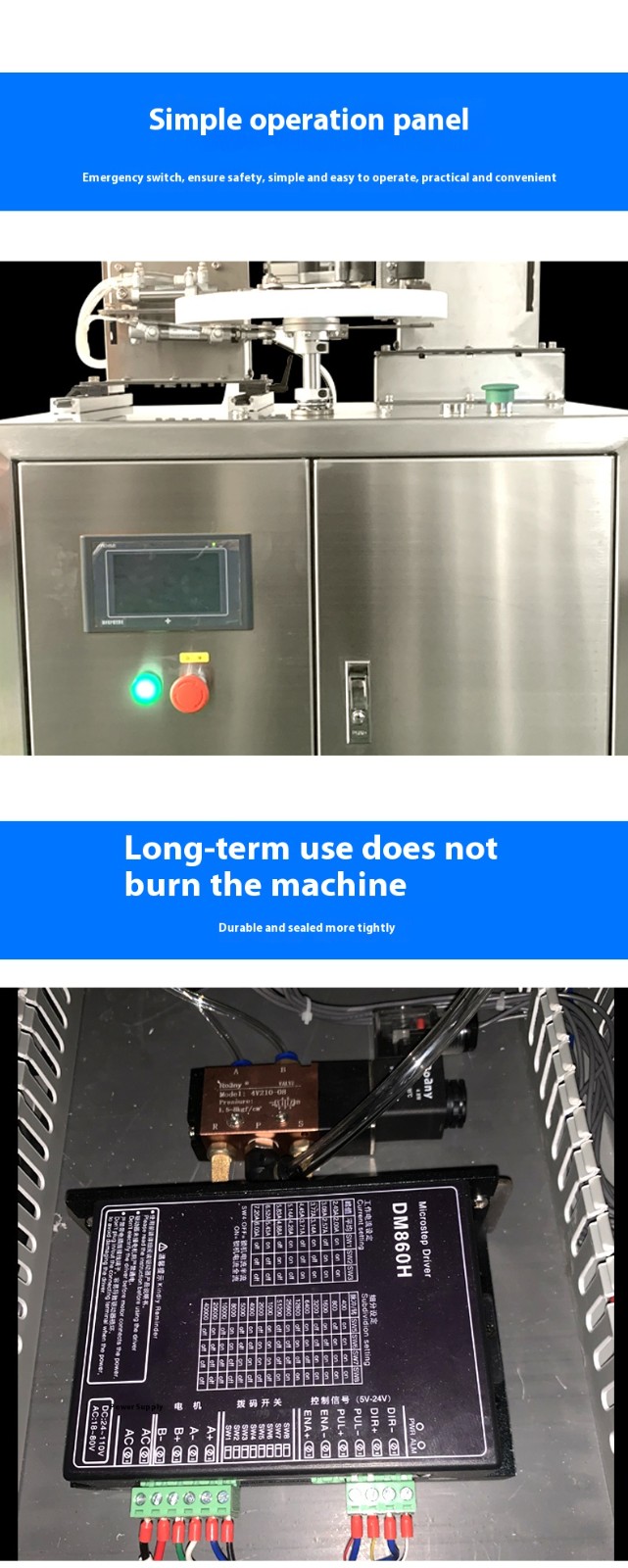

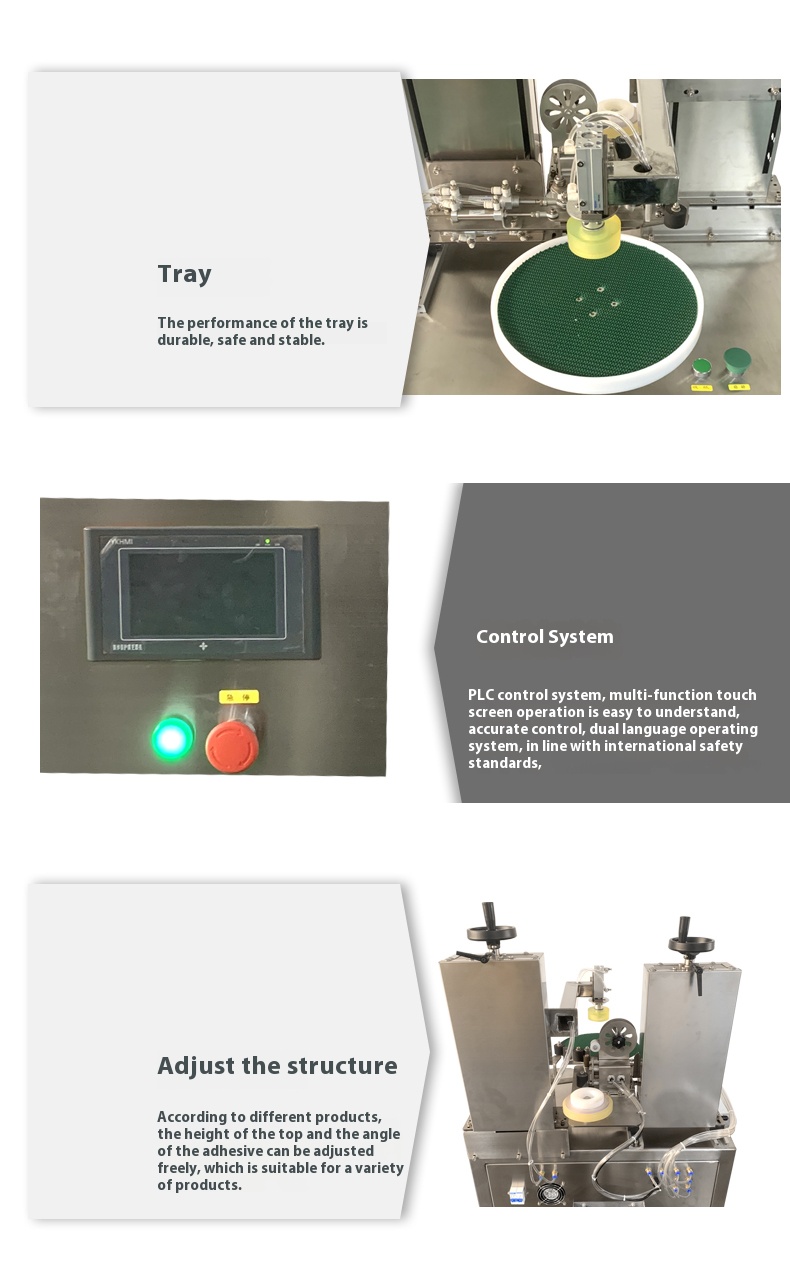

Most models adopt a humanized intelligent man-machine interface control system design, which makes the operation simple, easy to learn, and safe and reliable.

It is suitable for sealing cans and boxes of various shapes and materials. Some equipment can also meet the sealing needs of cans and boxes of different sizes and shapes by replacing molds, featuring multi-functional use with one machine.

It is widely used in industries such as food, pharmaceuticals, chemicals, and cosmetics, for the final sealing of products like chocolate boxes, candy boxes, mooncake boxes, tea cans, milk powder cans, and cosmetic packaging boxes.

- Material: Compatible with tin boxes, aluminum boxes, plastic boxes, paper boxes, foam boxes, wooden cans, etc.

- Shape: Supports round, square, rectangular, oval, polygonal (e.g., hexagonal, octagonal) and other special-shaped cans and boxes. Some models can be adapted to different shapes by replacing positioning molds.

The core of efficiency depends on the "automation level" of the equipment. Usually measured by the "number of sealings per minute", it is divided into two major grades—semi-automatic and fully automatic—to meet the needs of small-batch to large-scale production:

- Efficiency Range: 10-30 units per minute

- Operation Method: Manual assistance is required for loading and unloading (workers place cans/boxes into the conveying station, and after the machine completes sealing, workers take out the finished products)

- Applicable Scenarios: Small-batch production (e.g., daily output of 500-2,000 units), small workshops, and scenarios involving frequent switching of multiple product types in small batches, such as sealing handmade soap boxes and small tea cans

- Efficiency Range: 30-60 units per minute (some high-speed models can reach 80 units per minute, which needs to match the size of cans/boxes and the type of tape)

- Operation Method: Can be connected to a production line to realize the fully unmanned whole process of "automatic loading - conveying and positioning - tape sealing - automatic unloading" without manual intervention

- Applicable Scenarios: Large-batch and continuous production (e.g., daily output of 2,000-10,000 units), such as mooncake factories, milk powder can production lines, and mass packaging of cosmetic gift boxes